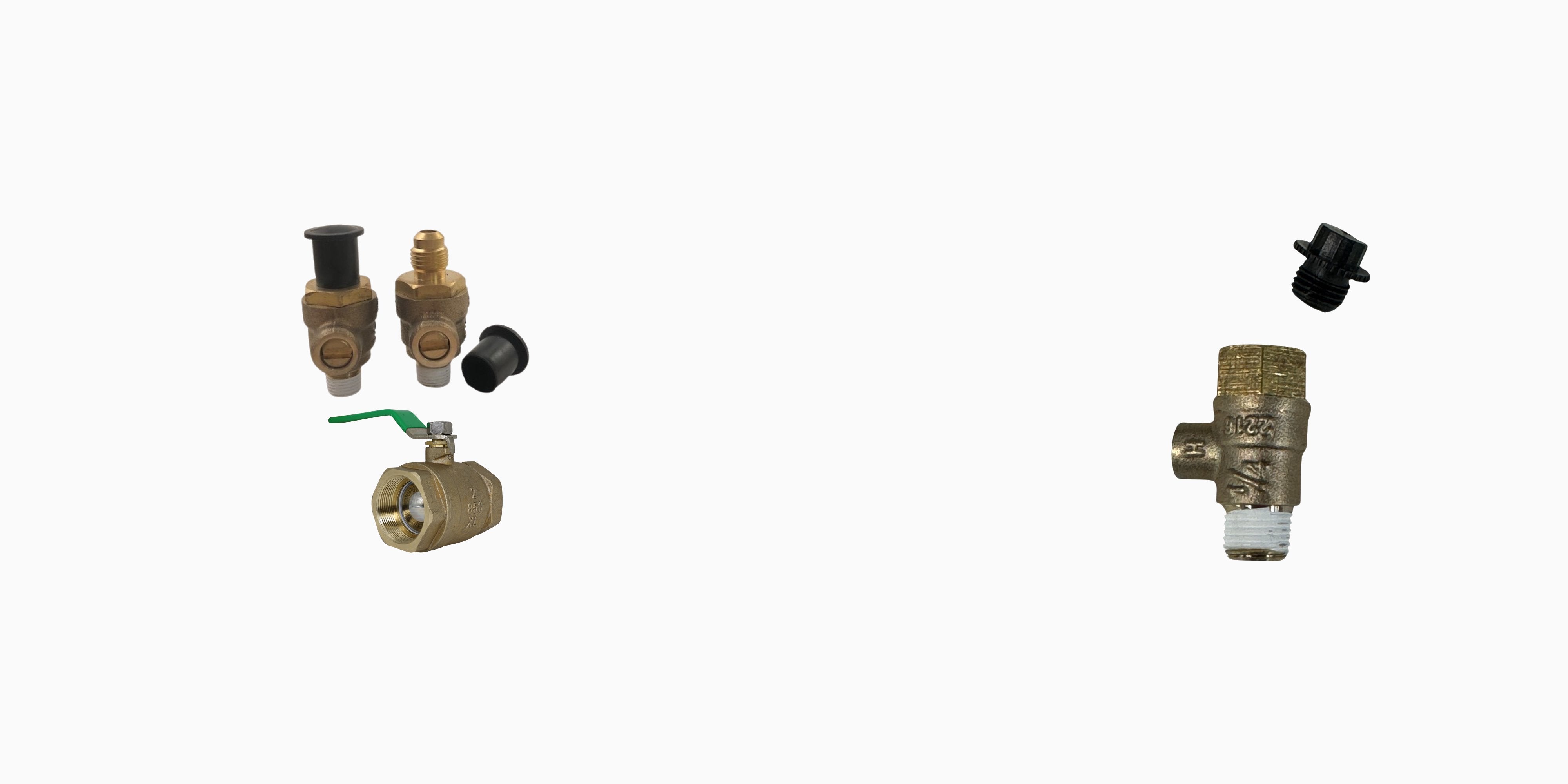

Backflow Seat Removal Tools

Video Transcript:

Hello once again this is Sean with

Backfill Supply out of Salt Lake City

Utah the last time I did a video I

showed you how to troubleshoot and work

on a particular 975 XL that was brought

in by a customer that was having

problems with the backflow assembly and

didn't want to do anything about it just

wanted a new one and as I was doing that

I told you I wanted to show you a video

on some seat removal tools and so that's

what the main purpose of this particular

one is tonight but I want to show you a

few other accessories as well the backflow seat

removal tools are made by different

companies. I'm not sure who started at

first if it was an aftermarket person or

if it was the manufacturers themselves

but the two seats that are the most

common that need to be removed are the

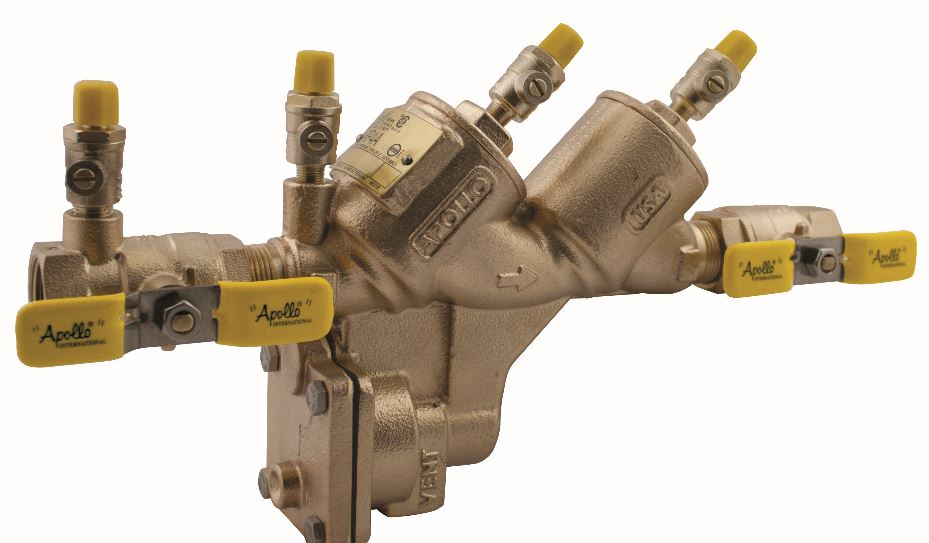

or Apollo remember Conbraco and Apollo

are the same company and they just have

played around with their name a little

bit and the seats are very similar these

are both out of the three quarter one

inch sizes the Conbraco or Apollo are

gray.

The one on the way right hand and the

Wilkins are the black ones that are used

in the 975 xl's 95 XL and the 95 XL

T's just a quick note about that the 95

XL T seats are different than the ones

that are used in the 95 XL in the 975

XL but they both have just four little

stubs that point into the center of the

seats and they look very similar both

the camber echo and the Wilkins similar

setup similar design as far as those go

they just thread into the body but they

can be difficult to get out and

sometimes people will try and ship them

out with a screwdriver or they'll try

and cut them out. I just had a person

last week tell me that somebody had

taken a saw blade and cut down into it

and they went through it and into the

threads and ruined the whole assembly so

the rock the proper tool can be an

important asset to any tester or person

doing a repair out there. Now I'll start

with the ones that are made by the

manufacturers

it's just a flat piece of metal it's

really not special it just goes in and

it makes contact on two of those those

stubs that point into the center and you

throw them in and out

you just put a wrench at the top of this

and I'll show you here in a second -

twist twist them in and out. The other

one is made by a guy out of Oregon and

he's the one that originally made the

quick-connect test fittings at which

we'll talk about here in a minute

and he's gone through different designs

through the years but this is the one

that he's settled on and it just uses a

ratchet that you'll put the extension

down in there and it locks into place

and you attach your ratchet to the other

end and you thread am in and out. Nice

compact strong tool and you'll notice

that there's a different and I'm not

sure I think that's a quarter inch size

for the three-quarter one inch seat

removal tool that you'll need it for as

well as the relief valve seat tool on

the inch and 1/4 to two inch and it's

the same thing with the Wilkins again

they look very similar very similar

design and they are definitely worth the

money.

His run about ninety five dollars for a

set these other ones that are made out

of aluminum are made by a local guy and

they're about $9 a set as I recall and

it also same principle it has four

little notches to make contact down on

to the four stubs in the seat and you'll

just hook your rent your extension into

it and connect your ratchet and you just

put it down inside the assembly line it

up and this one's a little bit easier

because I've done this several times

tonight as I've been trying to do this

video and once you have that loosen you

can remove the socket

and then it comes out so it's fairly

simple. These are not as good putting

them back in because they're not a tight

fit but they can help if once you get it

started but I have found that the this

Wilkins tool tonight and I haven't

noticed this on the one that I use here

in the office for customers when they

come in that it's holding fairly tight

and so that does help you to get it down

in there and get it started just make

sure that you have it started equally

all the way around so you don't cross

thread it and I never use a wrench when

I'm putting this back in I just snug it

with my hand and that's all that's

needed. Now just to show you taking it

out again you just put it down in the

center make contact on two of those

points and I just use a crescent wrench

across the top and use that to loosen it

it takes a few turns this tool to get it

started so it's loose enough so that you

can just unthread it the rest of the way

simple as that now I say simple as that

but I was struggling with this the very

first time tonight and actually bent the

tool a little bit so these Wilkins and

Conbraco tools from them can

bend and you just pound them flat again

and these are about I think the Apollo

ones are about thirty dollars and the

Wilkins ones are almost fifty. Now the

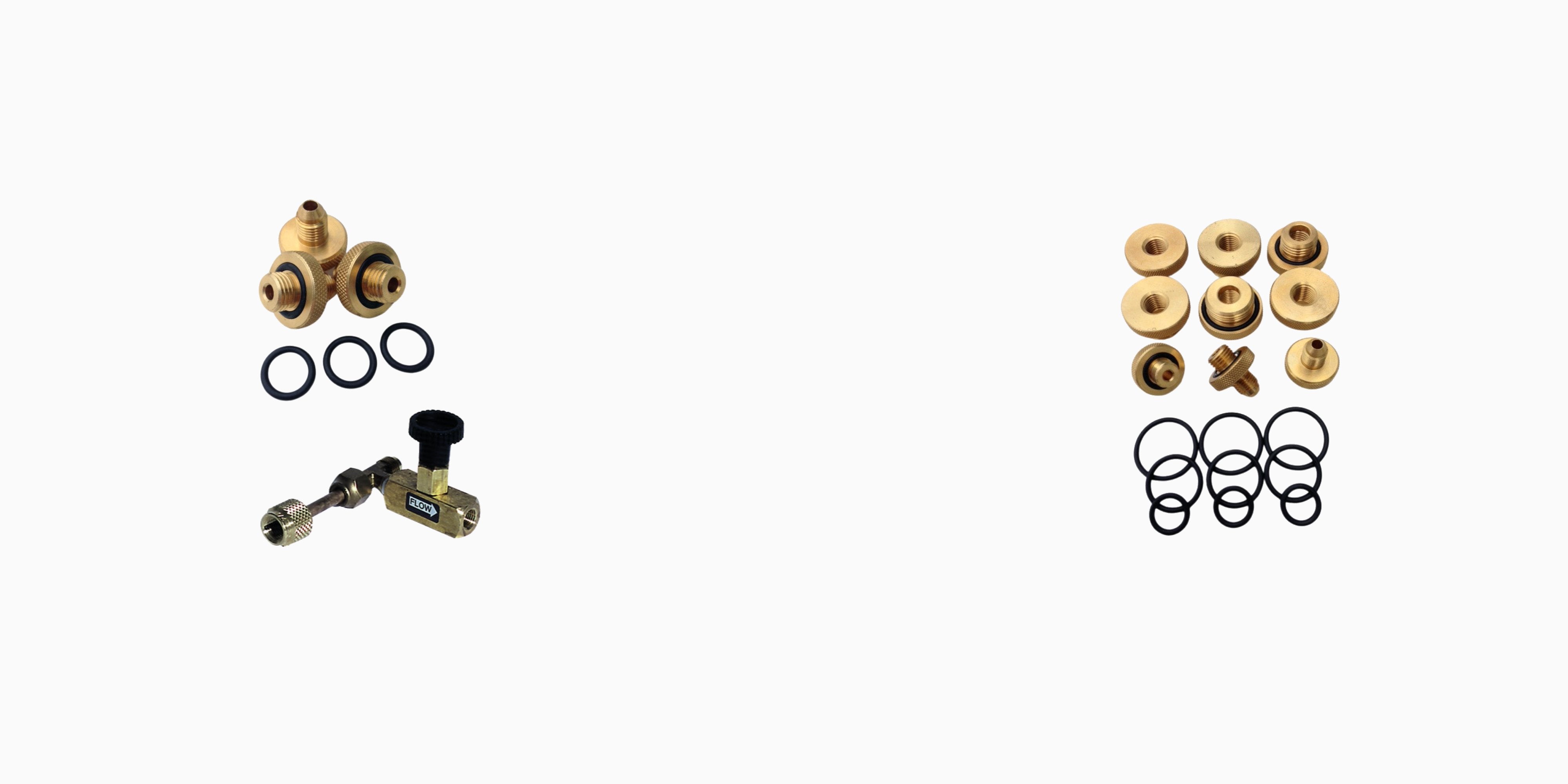

other thing I wanted to show you were

these Quick Connect adapters and they've

gone through a change when Tom the guy

out of Oregon originally designed these

they have an o-ring at the base of the

top and it just seals down at the top of

the test cock as you thread it in nice

and snug and it's tight against the top

and you'll want to lube those from time

to time so that the o-ring stays soft

and supple and that it lasts longer this

other design that he just fairly

recently came out with has a gasket or

an o-ring on the other sizes the half

inch and 3/4 that seals down at the base

and so you just thread that in until you

have a little bit of resistance and snug

it and hopefully you can see

how that there's a quite a gap between

the top of the test and the base.

Now his other one like I said has an

o-ring and the way that the ball valves

are designed these o-rings fit down in

there very nicely and you just snug it

down in there it's as easy as that

the brass ones again you still have the

o-ring at the base of the top or the

bottom of the O ring at the base of the

top of the fitting and you just snug it

down there and they're both quick and

easy quick turn them in turn them out

just don't forget to leave them and

that's the nice thing about these

colored ones they stand out a little bit

more and it makes it a little bit more

difficult to walk away and leave them at

three-quarter same thing and I didn't

bring the brass three-quarter ones out

because they're just like the others and

you can see the difference and how much

time that can save you. The frustration

is when you do leave them and hopefully

they're there when you come back the

next year but I do sell quite a few of

these because people will leave them or

they'll drop one down a drain, I'm amazed

time we go down a drain somewhere. Now

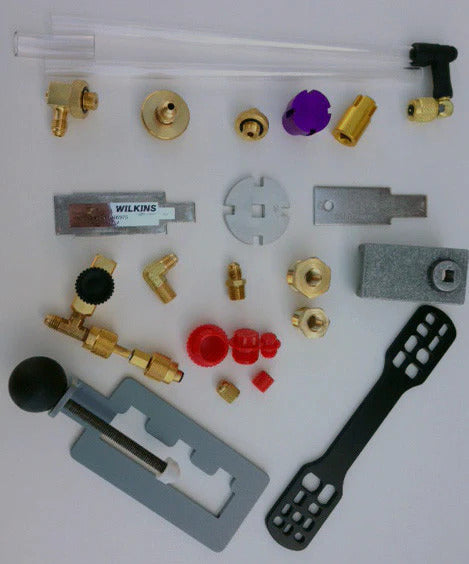

the other tools that I want to show you

is for the ball valves and I showed you

on that video last time using this

ball valve handle wrench and maybe I'll just

use it on the same assembly again and

you just put it on the handle of the

ball valve attach your socket and it

allows you to turn that really easy and

this is really beneficial when you've

got something that's down in a box

hopefully that's only on a double check

but it'll save your knuckles a lot of

times you try and use a wrench and it

slips off and you can do more harm than

good and so this is a beneficial tool

now that's for the 3/4 one inch

and possibly even 1/2 inch and a little

bit smaller that'll work on but he's

also got one that's made for the inch

and 1/4 inch and a half and two inch

size that also just sits around the

handle and you put your socket onto it

and turn it

not going to try and do that with this

one because it's very hard to do that

when they're not installed in line those

are a little bit more difficult to turn

but the other thing that I want to show

you is a bit a missing ball valve handle

wrench so this is designed to go onto

the stem if the handle is missing and

this particular tool has different array

civ of holes on both ends so it'll do

probably anything from the / inch up

to inch and you just find the hole

that fits closest to the stem that you

have. He also makes this where it's just

basically like that and it's just for

the one-inch and smaller assembly so it

doesn't have the other end and so you

just you need to remove the handle which

should be already done that's why you

have the tool in the first place you

find the spot that fits the best. Now

I've got the advantage of being able to

rotate the ball itself but in a box you

can't do that and sometimes you can only

get it so far so then you can pick it up

and then there's one that's a little bit

offset and you can finish turning it

very convenient and again it's the same

principle with the inch. So those are

the things that I wanted to go through

tonight with you I want to thank you for

your time I hope that you find this

helpful please post any questions or

comments down below and I'll respond

back to them and please click on

subscribe and click the bell so you're

notified of another video I will try and

do those once or once a week or once

every two weeks depending on how busy

things get and the availability of the

things that I need to make the video I

want to thank you again and appreciate

your time have a good evening.

Leave a comment